hardness test ts|hardness testing machines : importer Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality . Medium Season 1 Episode 14: In the Rough Summary: Things go from bad to worse when Allison's mother-in-law comes to visit. A once-closed case is re-opened to try to find out if .

{plog:ftitle_list}

Resultado da Larissa Manoela perfeição. 75 sec John-Marston-1911 - 720p. Larissa Manoela Gostosa Dançando #4. 58 sec Xputaria-Br - 360p. Eu implorando .

Conversion of hardness-to-hardness or hardness-to-tensile-strength values for unalloyed and low alloy steels and cast steel per. ISO 18265 - 2013. Hardness conversions are no substitute for direct measurements.Tensile strength = Bhn × 490 (for Brinell numbers larger than 175) The above .Several methods have been developed for hardness testing. Those most often . Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality .

The table below converts Brinell Hardness to Rockwell Hardness scales and vice . Tensile strength = Bhn × 490 (for Brinell numbers larger than 175) The above .Standardized optical hardness testing methods include the Brinell hardness test (ISO 6506, ASTM E10), Knoop hardness test (ISO 4545, ASTM E92, ASTM E384) and Vickers hardness test (ISO 6507, ASTM E92, ASTM E384). Tensile Strength (Approximation) Symbol: Approx. TS. An approximate relationship between the hardness and the tensile strength (of steel) is, where HB is the Brinnell Hardness .

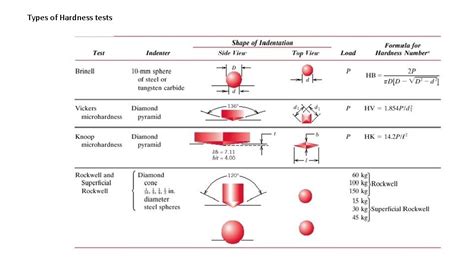

Several methods have been developed for hardness testing. Those most often used are Brinell, Rockwell, Vickers, Tukon, Sclerscope, and the files test. The first four are based on .The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In .

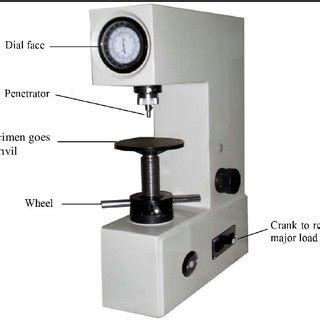

how hardness testing works

What is the Vickers Hardness Test? This procedure was developed in 1921 by Robert L. Smith and George E. Sandland during their work at Vickers Ltd. It was meant to be an alternative to the already-established . The ability of a material to resist permanent indentation is known as hardness. It is an empirical test, rather than material property. In order to define different hardness values for the same piece of material, there are .Learn more about material hardness testing. How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. . Ultimate Tensile Strength: 280 MPa: 510-540 MPa: _Yield Strength_ 140 MPa: 430 .The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The . Hardness and Tensile Strength. .

The Vickers hardness test is suitable for a wide range of applications, including micro hardness testing. On this page, you can find a description of the Vickers hardness test, practical information on how to apply it and a list of our micro hardness testing machines for Vickers. The Vickers hardness test at a glance: Ideal for micro hardness .The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .

What is Brinell Hardness Test? In Brinell Hardness Test, an indenter, a ball made of carbide metal (formerly hardened steel) with diameter D, is pressed in the test object surface and the diameter ‘d’ of the indentation is measured followed the test object force removal.. Brinell hardness HB (according to standard HBW) is proportional to the quotient of the testing force . 🧴Method 1: Simple Soap Test. The soap test is a great way to determine water hardness.It won’t tell you exactly how hard or soft your water is, but it’s a quick and easy indicator of whether or not you have hard water.. You will need: A clear plastic bottle with a lid; Pure liquid soap; A water sample from your faucet The hardness test is a way to assess the quality of a material, determine its properties, and evaluate its suitability for a specific application. What is Hardness Testing? Hardness testing is a mechanical test that measures a material’s resistance to indentation, scratching, or abrasion. The test is performed by applying a specific force on .

The Brinell hardness test was originally developed in the late 1800s by the Swedish engineer of the same name. He wanted to find a method to control the quality/hardness of steel. His solution was to press a railway wheel-bearing ball into the material and then measure the size of the mark it left. The method proved reliable and in 1900 the . (4) Selection of F and D (principle of geometric similarity of indentation) When measuring Brinell hardness with indenters of different diameters and loads of different sizes, the principle of geometric similarity must be met to obtain the same HB value, that is, the opening angleφ of the indentation is equal.. Method: The same HB shall be measured for samples with .a Brinell hardness values up to 450 HB w Brinell hardness values up to 450 HB were determined using a steel ball indenter, those above this value were determined with a hardmetal ball.. NOTE 1 Values in parentheses are those lying outside the defined range of the standard test method but which may used as estimates. NOTE 2 The value of the tension test are not based on method .

What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a mineral is defined as its "resistance to being scratched". A list of the Mohs Hardness Scale Minerals is shown in the table below.Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .

hardness testing techniques

When testing metals, indentation hardness correlates roughly linearly with tensile strength, [1] but it is an imperfect correlation often limited to small ranges of strength and hardness for each indentation geometry. This relation permits economically important nondestructive testing of bulk metal deliveries with lightweight, even portable .

The ultimate tensile strength and 0.2% yield strength of this steel correlated well with hot microhardness data at test temperatures up to 400°C using Cahoon's expressions sigmauts = (H/2.9)(n/0. .

With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness. Vickers hardness te. Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the .The Brinell hardness number can be correlated with the ultimate tensile strength (UTS), although the relationship is dependent on the material, and therefore . Brinell hardness test – Part 3: calibration of reference blocks". "EN ISO 6506-4:2014: Metallic materials – Brinell hardness test – Part 4: Table of hardness values". US .Welcome back to the Ask the Expert blog. The blog is designed to help educate you on all things retaining rings and wave springs. This week, we talk about tensile strength and why it’s important in wave spring and retaining ring design. To ensure you know how a material will perform in a working environment, several physical properties can be measured to better .

There are a number of different methods of testing the hardness of a material through indentation. The three most commonly used are the Brinell test, the Vicker’s Diamond test, and the Rockwell test. All three methods involve indentation of the material. The hardness is calculated by measuring the force applied and comparing this to some .

Tensile testing on a coir composite. Specimen size is not to standard (Instron). Tensile testing, also known as tension testing, [1] is a fundamental materials science and engineering test in which a sample is subjected to a controlled tension until failure. Properties that are directly measured via a tensile test are ultimate tensile strength, breaking strength, maximum . One key to identifying mineral species is to test its hardness. Mineral hardness tests can be performed at home or on a rockhounding field trip. There are necessary tools for express hardness testing: A fingernail, a Cooper coin (penny or 1,2.5 cents euro), a shard of glass, and a knife blade. Measuring the hardness of materials is a fundamental aspect of material science and engineering, involving various test methods each suited to specific types of materials and applications. These methods not only help in determining the hardness but also provide insights into other material properties like strength, wear resistance, and ductility.

The specific size, shape, and location requirements of the hardness test determine the use of the Vickers method. One of the key advantages of the Vickers Hardness test is its versatility, as it can be applied to a wide range of materials and properties. Vickers Macro Hardness testing standards we work with: BS EN ISO 6507-1:2018 (HV1, HV5, HV10)Rockwell Hardness Test. The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied. Hardness numbers have no units and are commonly given in the R, L, M, E and K scales. . The well known correlation links hardness with tensile strength, while resistance to deformation is .

Hardness testing is perhaps the simplest and the least expensive method of mechanically characterizing a material. This article provides an overview of the principles of hardness testing. It compares Brinell with Meyer hardness testing and hardness testing of fully cold worked metals with fully annealed metals. The article discusses the plastic .This article reviews the factors that have a significant effect on the selection and interpretation of results of different hardness tests, namely, Brinell, Rockwell, Vickers, and Knoop tests.

hardness testing standards explained

hardness testing scale

Baixar Dragon Ball Legends Dinheiro Infinito 2024 atualizado. Dragon Ball Legends apk mod oferece uma variedade de modos de jogo para explorar. Desafie o modo história e .

hardness test ts|hardness testing machines